Categories:

Energy

/

General Market Commentary

Topics:

General Energy

/

General Market Commentary

Battery Reality: There’s Nothing Better Than Lithium-Ion Coming Soon

Clean-energy visionaries have long argued that the world needs a better battery capable of selling skeptical consumers on electric cars and running the grid on renewable power. And yet the battery of the future—at least for the coming decade—will almost certainly be the battery of the past.

The humble lithium-ion battery has built up such a commanding lead in the market that competing technologies may struggle to catch up. That lead will only widen as a wave of planned new lithium-ion factories comes online in the next five years.

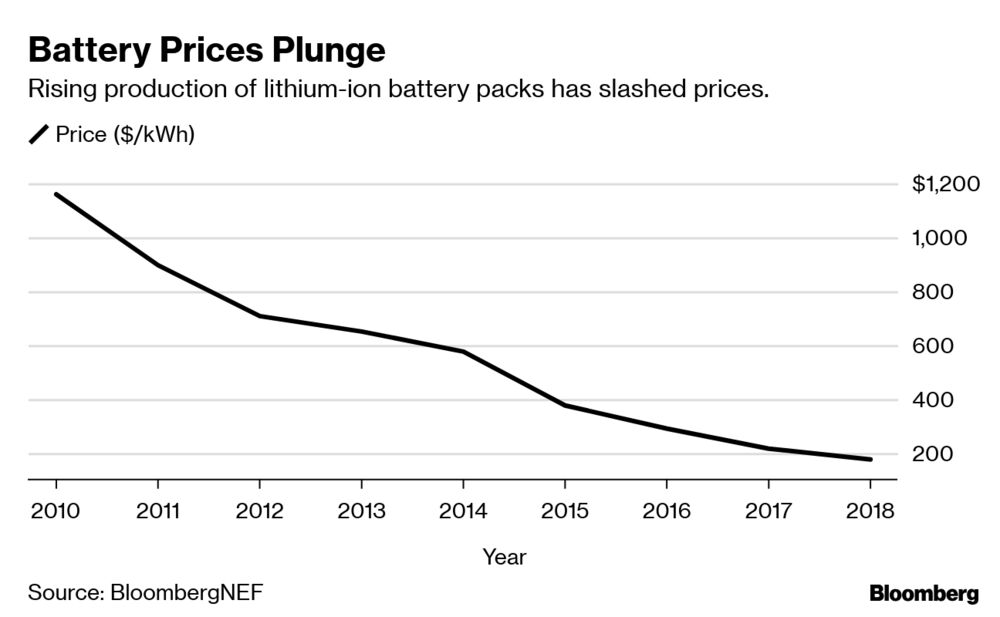

The batteries pouring from new factories in China, the U.S., Thailand and elsewhere will further drive down prices, which have already plunged 85 percent since 2010. And the billions spent on factories will create a powerful incentive for the industry to keep tweaking lithium-ion technology, improving it bit by bit, rather than adopting something else.

Many startups now focus on upgrading lithium-ion batteries rather than competing head-to-head. “We don’t think lithium ion is going to be disrupted,” said Erik Terjesen, senior director of licensing and strategy for Ionic Materials Inc. Terjesen’s Massachusetts-based company is one of several trying to perfect solid-state batteries, often billed as lithium ion’s likely successor. Solid-state batteries promise, among other things, to remove the flammable liquid that can cause lithium batteries in laptops and cars to occasionally catch fire.

But Ionic isn’t trying to replace lithium ion. Instead, the company has designed its polymer electrolyte to work inside existing batteries. That means all those new factories can use it without buying expensive new equipment. “We don’t believe, given all the investment in lithium ion, that people are going to throw that out the window and start over from scratch,” Terjesen said.

Invented by an Exxon Mobil Corp. researcher in the 1970s and commercialized by Sony in 1991, rechargeable lithium-ion technology has existed for decades. The basic battery works by sending charged lithium atoms, or ions, through a liquid electrolyte substance, shuttling back and forth between a positive cathode and negative anode. Tinkering with different materials in the cathode—cobalt, nickel and manganese—has increased the amount of energy the batteries hold. What started out inside consumer electronics such as cordless phones can now be found in electric cars and connected to the power grid.

“It’s a very versatile technology, so every time it gets cheaper, that opens up more demand segments for it,’’ said Logan Goldie-Scot, head of energy storage research at BloombergNEF. Lithium-ion battery pack prices, which averaged $1,160 per kilowatt hour in 2010, reached $176 per kWh last year and could drop below $100 in 2024, according to BloombergNEF. The continuing drop in prices combined with improved performance will likely open new markets.

Not everyone is convinced that lithium-ion can do it all. Some big automakers pine for a breakthrough technology that will enable a long-range electric vehicles, capable of traveling perhaps 500 miles on a charge, that will finally persuade reluctant consumers that they won’t run out of power on the road. Toyota Motor Corp., for example, has far more patents and patent applications for solid-state batteries than any other company and is investing $13.9 billion in its battery operations.

The need to store renewable power in bulk could require alternative battery technologies. Although companies such as Tesla Inc. and Dynegy Inc. have already begun plugging lithium-ion batteries into the grid, the installations typically supply electricity for just four hours. Former U.S. Energy Secretary Ernest Moniz, in a February interview with Bloomberg, said that kind of short-term energy storage won’t help integrate large amounts of renewable power. “It’s not going to handle a day, a week, a month, a season,” said Moniz, who recently co-wrote a report calling for far more research investment in batteries. “That’s why you need different approaches.”