Categories:

Energy

/

General Market Commentary

Topics:

General Energy

/

General Market Commentary

Cobalt price boost as electric vehicle loadings surge

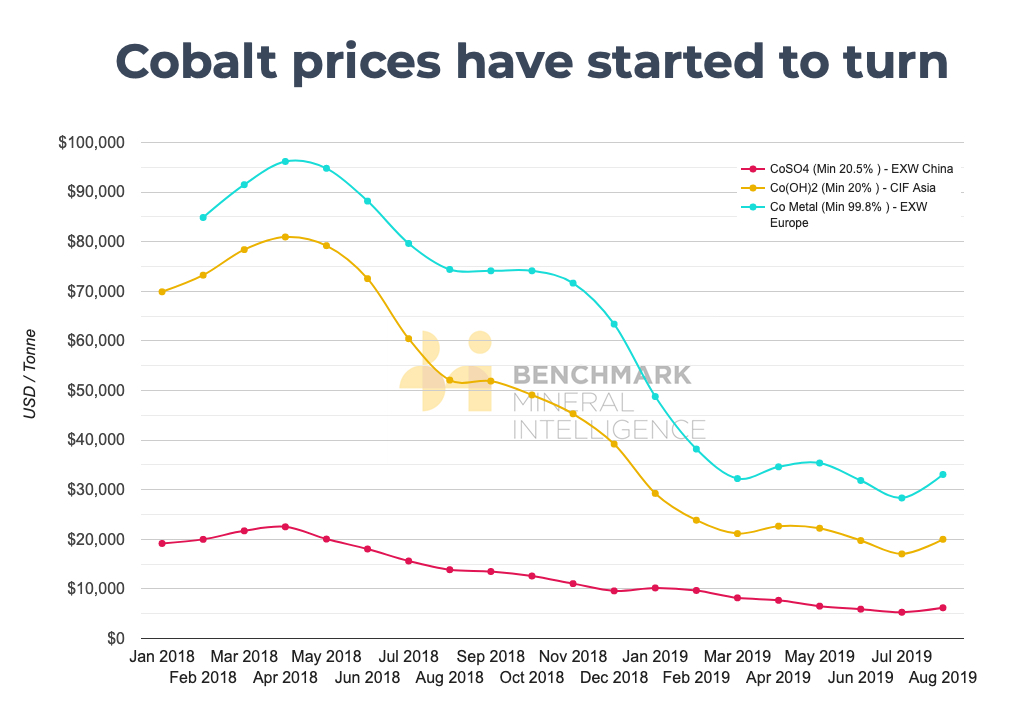

After hitting near decade highs in March last year within a stone’s throw of $100,000 per tonne, cobalt prices fell off a cliff.

Glencore’s decision last month to mothball the world’s largest cobalt mine breathed new life into the market, but so far the response has been relatively muted with the metal still trading in the mid-$30,000s.

Even at these levels, cobalt is a pricy raw material for electric vehicle manufacturers and battery makers have been working hard to find a substitute for cobalt, or at least reduce the required loading.

First generation Nickel-Cobalt-Manganese (NCM111) batteries had a chemical composition of 1 part nickel, 1 part cobalt and 1 part manganese. NCM batteries with lower cobalt content (622, 523 chemistries) are quickly becoming the standard in China, which is responsible for half the world’s electric car sales, and a much greater proportion of EV battery manufacture.

The industry is now fast moving towards even higher nickel content at the expense of cobalt and manganese with the market share of NCM811 increasing rapidly although it still only represents a tiny portion.

Tesla is a proponent of nickel-cobalt-aluminium (NCA) technology which requires less than a third the amount of cobalt and the EV pioneer says the batteries in its latest model already match NCM811.

A new report by Adamas Intelligence suggest despite the ongoing thrifting of cobalt in batteries deployed by EV manufacturers, the per vehicle loading of cobalt jumped by 45% in the first half of this year compared to H1 2018.